During our 40+ year history, we have utilized a vast array of products and building systems. As a Design-Build contractor, it has been our responsibility to select the appropriate products and construction method to provide our client with the most economical process that meets or exceeds utilitarian demands, efficient operation and aesthically satisfactory product.

During our 40+ year history, we have utilized a vast array of products and building systems. As a Design-Build contractor, it has been our responsibility to select the appropriate products and construction method to provide our client with the most economical process that meets or exceeds utilitarian demands, efficient operation and aesthically satisfactory product.

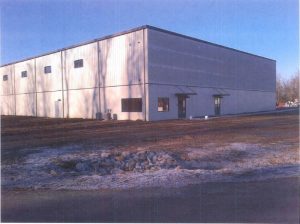

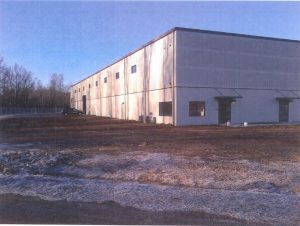

Currently we are constructing a 31,250 square foot building for Source Recycling in Clayton, NC. In this environmnet, the end-product required a strong, low-maintenance facility generally unaffected by moisture and weathering with maximum tolerance and adversity to fire. Tilt-Up construction is a fast, simple, economical process that meets all of the needs of client and end-user.

Technically tilt-up construction is a simple form of precast concrete construction. The technique utilized on this project is on-site prefabricating concrete wall sections (panels) in a horizontal position on the building’s floor slab. The formed concrete panels are then tilted to a vertical position tying into building’s roof and floor system.

Tilt-up construction requireds detailed ogranization and planning and must follow a carefully orchestrated construction plan. It is a step by step procedure that cannot be short-circuited nor rushed.

It is a mothod that must be planned in advance of construction start. Owner and contractor must plan and determine if this process and end product best meets needs of the owner.

If you are considering a new building with volume and size needs, I encourage you to discuss your needs and the possibility of tilt-up construction.

I invite you to view the project photos attached and follow the project in pictures as we move forward and complete the project.